MEMS Force Sensors Give Listeners a Better TWS Experience

January 10, 2024

In my last blog on MEMS force sensors, I talked about how HMI sensors in so many devices—from our watches to complex machinery—have changed how we get information and how we interact with technology. Where, in the past, so many devices had nothing but mechanical buttons or keys, they now have touchscreens and other sensing technology to control and set options. Buttons are still needed on some devices, which create complexity in manufacturing and quality testing when they’re mechanical. And I also introduced how Qorvo’s MEMS force sensors eliminate mechanical buttons so product engineers can create gapless designs. Qorvo force sensors are sensitive enough that designers can use any material—even up to two inches thick. These sensors help simplify manufacturing and reduce costs.

So now, let’s look at an application: True Wireless Stereo (TWS) earbuds and their multi-function buttons (MFBs).

The Challenges of TWS MFBs

One of the most commonly used everyday devices where MEMS force sensors can replace mechanical and capacitive MFBs is TWS earbuds. Nearly all of us use earbuds for when we’re on a call, video conferencing, watching our favorite streaming series, on a run or at the gym.

Once we pair them with our phone, tablet, PC or TV, we tap—or more likely, push—the MFB built into each earbud to control what we hear. Often these buttons are simple mechanical contacts. Some of the more expensive versions use capacitive touch sensors. Each design option introduces challenges for the engineer and manufacturer.

Transforming Touch with Qorvo SensorFusion™

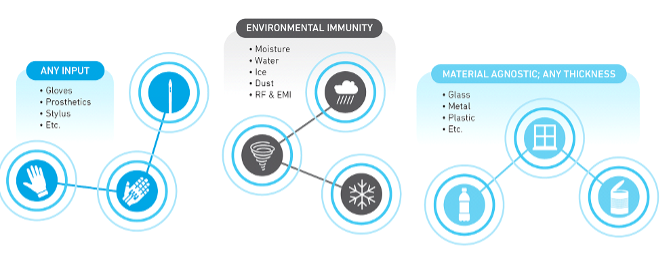

Qorvo's sensors transform touch and elevate your end user's experience. Our technology works with a multitude of inputs, is immune to most environmental factors and works with any material.

The challenge for mechanical buttons is the need for seals to keep the contacts dry, as sweat and other moisture can cause the switches to fail if the seals leak. These seals must be tested to meet adherence to any IP specification the manufacturer claims, adding steps and cost to the manufacturing processes. Additionally, these mechanical assemblies are larger than Qorvo’s force sensors. Their functionality can be applied under any surface, using any material, without requiring the mechanical components used in traditional buttons. These force sensors are thinner and have simpler designs.

Capacitive touch sense technology eliminates the physical contacts in a button—and their seals—but it also has its own challenges. Capacitive touch becomes less or non-responsive when you wear a glove or if it or your finger gets wet. You can also activate unwanted functions if the earbud doesn’t fit properly and requires touching it to readjust the fit. These are all potentially unwanted experiences for the listener.

Some more innovative TWS designs use a dual capacitive force sensor to detect when the stem is squeezed slightly to execute functions. The same design uniquely allows sliding on the stem of the pod to change the volume. While an innovative design using capacitance, they are complex and thus expensive to manufacture. And the same challenges with capacitive sensing remain for the sliding function.

Designers and manufacturers are always looking for simpler ways to design and less expensive, more reliable technologies in manufacturing. Qorvo MEMS force sensors fit both of those needs, as well as providing a simpler more cost effective solution.

Force-Sensing MEMS for Earbuds

Qorvo MEMS force sensors are silicon-based devices mounted on a printed circuit board (PCB). PCB manufacturing is extremely mature, reliable, and cost-effective. Using a MEMS force sensor eliminates the challenges with capacitive touch and slide and simplifies manufacturing—it’s a tiny, commercially available device mounted on a very small PCB. They allow the use of any input and any material with high environmental immunity.

Qorvo MEMS force sensors are highly sensitive under any surface—up to two inches thick. While TWS devices aren’t that big, they illustrate how sensitive the sensors can be for extreme design cases. The ability to choose any material for the design gives industrial designers options to make unique devices that can differentiate them in the marketplace, giving them a competitive edge.

Earbuds are among the smallest devices we use, so components are built on an ultra-small scale. Users want to listen with them for hours, which means the electronics need to draw very little current. It’s true capacitive touch and mechanical buttons draw no standby current, while MEMS devices draw some. But Qorvo MEMS force sensors and controller ICs can draw less than 1 μA of standby current without affecting the listener’s aural experience while making their usage experience so much easier.

Qorvo MEMS force sensors can also detect different levels of pressure on them, giving designers more options to create unique functionality. An application can be programmed to respond to single or multiple taps, varying pressure, and press and hold. For example, a single light tap can activate one function, while a firmer press might select a parameter or change volume. A single sensor allows imaginative designs.

There are other force sensors on the market, but they are not all the same. Qorvo MEMS force sensors are silicon chips that can sense micron and even nanometer deflections in the overlaying surface, allowing highly sensitive functionality with very thick and rigid surfaces, such as aluminum, steel, and carbon fiber. Because they’re silicon devices, they are perfect for earbuds, where size and low power are critical to a product’s success. The smallest Qorvo device measures 0.7µ m x 1.1 µm.

Qorvo MEMS force sensors give engineers the creative design freedom they have not had with mechanical buttons and capacitive touch sensors. Functionality can be enabled under any surface, using any material, with any shape, without requiring complex components, such as seals, and the difficulties that go along with them. These sensors give designers new options for more unique and differentiated products.

Achieving Successful Designs with Force Sensors

With the ability to eliminate mechanical and capacitive components and to use different materials, MEMS force-sensing silicon devices are ideal for imaginative designs for TWS earbuds. When considering a force sensor, it’s important to consult with a manufacturer to help ensure the success of the design. At Qorvo, we collaborate with customer designs from the start – at the visionary stage. Being early in the design we can provide insight into a design and help engineers select and integrate devices to achieve the successes they seek. We also work closely with 3rd party firms and distributors to enable easy and seamless production.

Qorvo offers some of the most sensitive MEMS force sensors in the industry. Qorvo MEMS sensors are very small, predictable and low power, enabling low-cost, reliable applications. Qorvo also can offer design expertise and assistance, simulation capabilities, and software integration to help engineers deliver product innovations across multiple markets, several of which include significant Qorvo design wins. Learn more about force sensors and how Qorvo can help you integrate them into your next project.

Have another topic that you would like Qorvo experts to cover? Email your suggestions to the Qorvo Blog team and it could be featured in an upcoming post. Please include your contact information in the body of the email.