Ultra-Wideband Case Study: Shedding More Light on UWB

February 14, 2024

In the modern factory, Ultra-Wideband (UWB) technology can tell you precisely where a product or part is in your facility with incredible accuracy. But why is that important? Does it really matter if widget A is on this shelf or that shelf? The short answer is "absolutely"—and UWB is already changing the future of manufacturing.

Creating a digital model of a factory allows operators to optimize their processes and better promote safety. Both of those considerations become more informed by tying who, what, when and where to people, tools, supplies, goods, machinery and events—and it can all happen in real time.

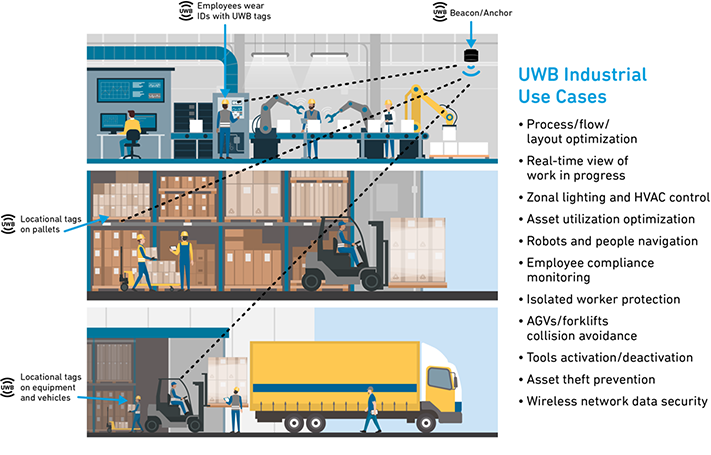

UWB technology has revolutionized location and communication capabilities, surpassing previous technologies in terms of accuracy. This technology is responsible for micro-location services, where radio anchors accurately pinpoint tags within a few centimeters. Micro-location provides real-time information and enables analytics systems to instantly measure, analyze and send alerts. Figure 1 illustrates examples of efficiency and productivity that are enhanced by using UWB in an industrial environment.

Current location-based technologies such as GPS, Wi-Fi and Bluetooth® Low Energy cannot achieve the level of precision required in manufacturing factories. GPS, with its precision within ten meters, greatly impacted retail e-commerce and eliminated the need for bulky map books. Wi-Fi improved location accuracy even further, while Bluetooth Low Energy can locate objects within a few feet under ideal conditions. However, today’s industrial and business applications demand higher precision and reliability. This blog post provides an example.

Learn How UWB enables micro-location to transform factories so manufacturers can optimize processes and safety.

Case Study: VELUX Modular Skylights

Ostbrirk, Denmark’s VELUX Modular Skylights recently transformed itself to modernize manufacturing operations and embrace digitalization. They accomplished this by creating a digital replica of their factory floor, a “digital twin.” This digital twin allowed operators to monitor, track, trace and analyze their entire manufacturing process, covering an area of 2,304 square meters (2,756 square yards).

A crucial aspect of this system was real-time location tracking of people and machines using UWB technology. This included forklifts and automated worktables (AGVs) responsible for moving work in progress (WIP) throughout the site. These AGVs were designed to adjust to the height of each worker, and that helped create a safer and more ergonomic work environment.

The VELUX solution utilized 12 UWB anchors and 59 UWB tags to track various objects. The AGVs moved the WIP to specific stations where skilled workers performed necessary jobs. The system then identified the nearest worker and adjusted the equipment to the appropriate height, ensuring a comfortable and safe working experience. If a worker was unavailable at a particular station, the system promptly alerted another nearby skilled worker to complete the task. The data obtained from tracking the movement of materials and personnel was processed to provide real-time information to managers. The data was instrumental in understanding and improving plant productivity, increasing worker safety, as well as managing machine maintenance.

Thanks to the implementation of a UWB-based RTLS (Real Time Location Systems), VELUX was able to chalk up significant benefits:

For more than 80 years, the VELUX Group has created better indoor environments by bringing daylight and fresh air into homes and other buildings all over the world. The VELUX Group was founded in Denmark and is today an international company with a presence in 36 countries. Get more information at VELUX.com.

- An increase in productivity of 10 percent through better shop floor management.

- Boosted maintenance performance by 50 percent.

- Decreased WIP by 10 percent.

How UWB Achieves Remarkable Precision

In industrial and commercial settings like the one described above, there are often large objects like walls, vehicles and machinery made of metal. These environments can cause issues for traditional technologies like GPS, Wi-Fi and Bluetooth Low Energy. GPS signals struggle to penetrate industrial structures, while narrow-band Wi-Fi and Bluetooth Low Energy signals get weakened, reflected or lost while negotiating around objects.

On the other hand, UWB technology overcomes these challenges and provides highly precise ranging and location capabilities. Instead of relying on narrow-band signals, UWB radios transmit signals with very low energy spread over a wide bandwidth. These signals have faster pulse rise and fall times, ensuring better signal quality and reducing the impact of reflections and noise spikes. This approach also simplifies the infrastructure by requiring fewer components.

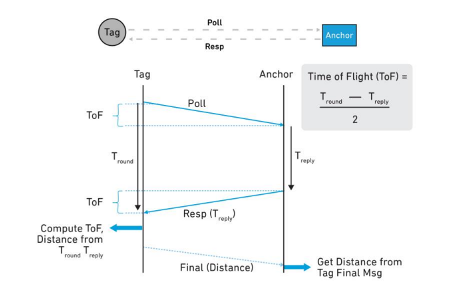

UWB utilizes a method called Time of Flight (ToF) to measure the distance to a tag. Various techniques, such as Two-Way Ranging (TWR) and Time Difference of Arrival (TDoA), improve the accuracy of distance measurement while mitigating the effects of signal reflections caused by walls and machinery. Other UWB ranging methods, like Phase Difference of Arrival (PDoA) and Reversed TDoA (RTDoA), offer benefits for different deployment scenarios. By using these different ranging techniques, UWB can accurately determine both the distance and direction (vector) to an object.

Learn how Qorvo's ultra-wideband (UWB) technology opens up new possibilities within mobile, automotive, industrial and IoT markets and applications.

Have another topic that you would like Qorvo experts to cover? Email your suggestions to the Qorvo Blog team and it could be featured in an upcoming post. Please include your contact information in the body of the email.