Closing the Gap: How Force Sensors Fuel Novel HMI Designs

August 15, 2023

The more informed we humans are, the better decisions we can make. Today, with all the sensors at our disposal feeding us data that applications turn into valuable information, we are the most informed people in history.

Our mobile phones alone have built-in sensors that tell us an immense amount of information. GPS receivers locate where we are with meter-level accuracy—some new phones with Ultra-Wideband (UWB) can locate within centimeters. Accelerometers gauge how quickly we’re going. Magnetometers determine which direction we’re headed. Smartwatches add heart rate detection and can even identify occurrences of atrial fibrillation and measure blood pressure.

And then there are the sensors that give us control of devices.

Human-Machine Interface (HMI) sensors have been around for a long time to detect a change in activity or measure something. If you’re old enough to remember the rotary dial telephone, it has a simple switch to detect phone number digits. As the rotating dial returned to its home position, the switch would click off from one to ten times. Repeat seven times—ten-digit dialing came later—and your favorite aunt would answer.

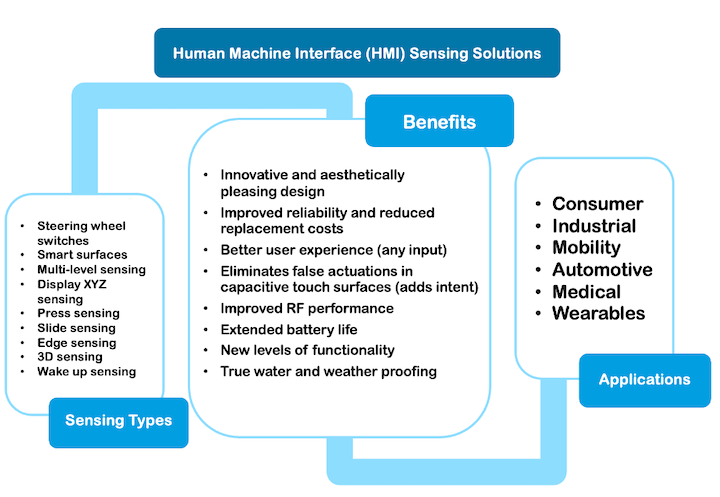

As personal devices, like simple watches, became more sophisticated, multiple HMI buttons appeared, giving us access to more functionality. Today, everyone is familiar with HMI sensors, especially touch-sensitive devices built into tablets, phones, watches, automotive systems, machinery and even your fridge. The evolution of sensors has changed our lives, making it much easier to interact with more innovative technologies.

Transforming Touch with Qorvo SensorFusion™

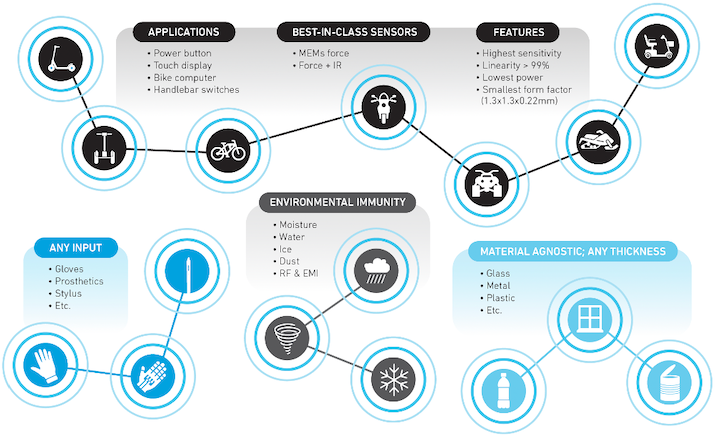

Qorvo's sensors transform touch and elevate your end user's experience. Our technology works with a multitude of inputs, is immune to most environmental factors and works with any material.

The Touchy Interface

Capacitive touch sense technology is by far the leading sensor technology used today. It’s often built into a display. Your finger sets up a capacitive delta across the glass to identify where it is on the surface. The HMI software does the rest, associating the location with a function—whether it’s activating a button, drawing a line or changing a parameter as you move your finger, or setting a function as you hold your finger on the spot. Some HMIs add strain gauges, image sensors (e.g., for fingerprint identification), or simple buttons in unique ways. The modern mobile phone combines many of these into a complex mechanical design.

Capacitive touch sensing has made it possible for us to use our finger or stylus designed for touch screens. It works wonders but becomes less responsive when you need to wear a glove for protection or if it gets wet or affected by other environmental conditions. There are special conductive gloves that work with capacitive touch and some thin gloves do activate the technology. Sensors based on strain-gauge and resistive technologies vary in performance and reliability with environmental conditions, which can lead to false positives or non-sensing buttons and less reliable HMIs.

When capacitive touch needs to be combined with other technologies, the mechanical aspects of the design become more complicated. With physical and mechanical buttons, for example, to meet dust and moisture resistance requirements, seals must be added. Special testing is also needed to ensure that the resistance and reliability requirements are met. When complexity goes up, costs can increase.

Force-Sensing MEMS Devices for Richer HMIs

Modern force sensor technology enables ‘gapless’ designs by integrating a highly force-sensitive device under any surface—sometimes more than two inches thick. Force-sensitive devices eliminate the need for mechanical buttons, as well as simplify a design and its requirements while providing functionality that responds to touch irrespective of how the pressure was applied—gloved or non-gloved hand; stylus, pencil or other object—or environmental condition—wet, dry, dusty, etc.

The gapless design removes many challenges that designers and users face. The need for seals and testing their effectiveness can be eliminated. Instead of flexible materials for buttons and the crevices often found with physical buttons—where dirt and bacteria can hide—surfaces can be smooth, making cleaning and care much simpler. This is especially important in clean-room and healthcare applications.

Regardless of whether a touch surface is made of plastic, leather, glass, carbon fiber, or more, Qorvo's force sensors provide high performance in any industrial design. Our solutions recognize touch from any input in any environment, enabling truly gapless and waterproof designs.

‘Solid surface’ is a relative idea. Most surfaces deflect even the tiniest amounts with pressure, allowing force sensors to detect changes. HMIs designed for the toughest environments might need very sturdy and thick surfaces with ‘bulletproofed’ displays. Some highly sensitive force sensors can detect the slightest pressure applied to a plastic surface over two inches thick—flat or curved.

Force-sensing devices can also detect different levels of pressure on them. An application can be programmed to respond to varying pressure, making the button multi-functional. A light press can activate a function, a harder press might select a parameter and the hardest pressure might change that parameter. Innovative HMI designs can be built from a single sensor.

Not all force sensors are the same. Qorvo force-sensing devices are MEMS silicon chips that can sense micron and even nanometer deflections in the overlaying surface, providing highly sensitive functionality with very thick surfaces. These very small silicon devices are easy to fit into nearly any design and draw very little power, making them ideal for mobile and portable devices, such as phones and wearables.

While force sensors alone can be populated under a surface for multiple functions, these sensors can also be combined with other technologies, such as capacitive touch, to build sensitive, reliable and innovative interfaces. For example, combining force sensing with capacitive touch can create a gapless functional interface that combines intent with location to reduce or even eliminate false positives.

Force-sensing devices offer engineers a new realm of creative freedom. Functionality can now be applied under any surface, using any material, with any shape, without requiring complex components, such as seals, and the difficulties that go along with them. Gapless designs on mobile phones without the use of physical buttons are now easily achievable with these sensors.

Qorvo’s Innovative Human Machine Interface (HMI) Technology in 2-Wheeler/μ-Mobility Applications: Qorvo’s HMI sensors transform power buttons, touch displays, bike computers and handlebar switches into sleek, intelligent controls, operates with a multitude of inputs, are immune to most environmental factors and work with any material.

Achieving Successful Designs with Force Sensors

MEMS force-sensing silicon devices are ideal for next-generation, gapless designs. Careful integration depends on several factors. Placement, sensitivity, overlaying materials, the software and other technologies that might be used are all important to the successful integration of a sensor in a design. Thus, when considering a force sensor, it’s important to consult with a manufacturer to help ensure the success of the design. The manufacturer can provide insight into a design and help engineers select and integrate devices to optimize the design.

Qorvo offers some of the most sensitive MEMS force sensors in the industry—providing extremely small, predictable and low-power options, enabling low-cost, reliable applications. Qorvo can also offer end-to-end design expertise and assistance, simulation capabilities and software integration to help engineers deliver product innovations across multiple markets, several of which include significant Qorvo design wins.

Learn more about force sensors and how Qorvo can help you integrate them in your next project.

.png?la=en&hash=571E5AB17A9525A307B51122AB240F4AE2D0A192)