Inside the Smart Factory Revolution: How UWB Redefines Manufacturing Efficiency

April 30, 2025

Hop into a time machine and look back at a manufacturer in, say, the 1980s. Would that company fare well with its day-to-day practices today? Probably not. Manufacturing these days isn’t just manufacturing. It’s smart manufacturing. Germany’s high-tech powerhouse Trumpf has emerged as a pioneer in smart manufacturing—leading the way with its adoption of Ultra-Wideband (UWB) location technology. With roots in precision tooling and a global reputation as the market leader in laser cutting and sheet metal machinery, Trumpf’s success now also includes a smart factory transformation powered by Qorvo’s UWB chipsets and omlox’s real-time location solutions. Trumpf’s journey offers a compelling story of how advanced location technology can drive real-world operational gains and position a brand at the forefront of Industry 4.0.

Precision Tools to Precision Tracking

Trumpf began its UWB journey years ago, deploying real-time location systems (RTLS) at multiple manufacturing sites, including the United States, Germany and Austria. According to Eberhard Wahl, CEO of Trumpf Tracking, the impact was immediate and significant. “Overall productivity went up dramatically,” he said. “On-time delivery improved. And perhaps most impressively, we reduced failure rates in sheet metal production—all just from implementing RTLS.” The secret to these gains? Qorvo’s 3000-series UWB chipsets, which power omlox’s real-time location products. These chipsets provide the precision, reliability and resilience necessary to thrive in highly reflective industrial environments—where traditional technologies like RFID or Wi-Fi often fail.

Why UWB? Precision That Scales

As factories digitize, simply knowing where a part or tool isn’t good enough. They need accurate, real-time, 2D (and eventually 3D) visibility—especially to achieve the higher tiers of digital transformation. “Starting from level 3 of Industry 4.0 maturity, accurate location data becomes essential,” Wahl explained, referencing an independent Fraunhofer study. “And once you reach level 4, there's really no other technology besides UWB that can deliver the performance needed.”

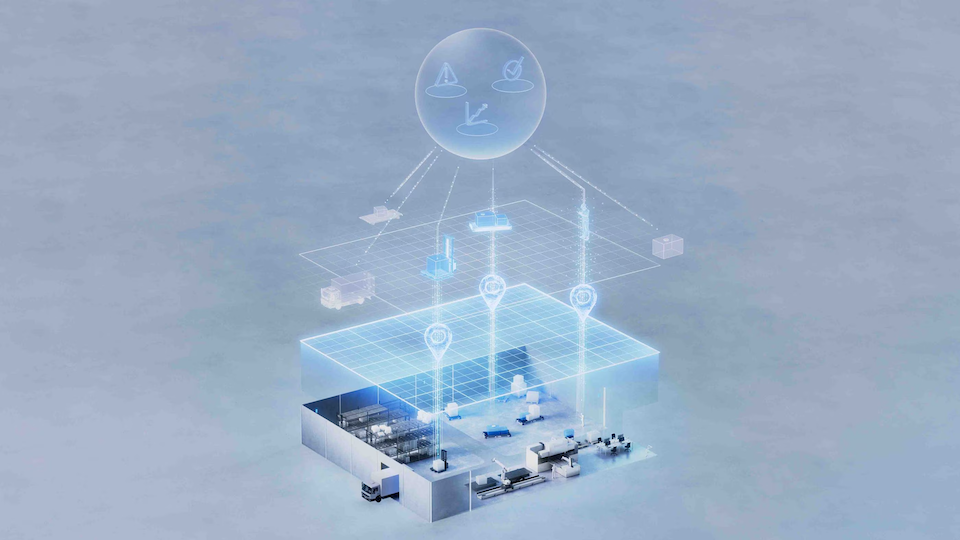

UWB stands apart for its multi-reflection capabilities, which are vital in complex factory layouts filled with metal surfaces and moving machinery. According to Wahl, this is exactly where Qorvo’s chipsets excel—enabling accurate positioning that allows digital twins, autonomous mobile robots (AMRs), power tool tracking, augmented reality navigation and more.

Strategic Sensor Placement and Use Cases

Trumpf’s deployment was methodical, starting with basic use cases such as tracking work orders and materials. Over time, the system expanded:

- Tags and sensors were placed on products, tools, transport units (like AMRs and forklifts), operators and equipment.

- Use cases evolved to include real-time production planning, quality management, AR-guided workflows and HEV navigation.

“You don’t start by tagging everything,” said Wahl. “But you need to plan for that future. That’s why we say, don’t start with RFID—it’s a dead-end at level 3. Begin with a UWB-based, multi-use case capable environment.”

The omlox Advantage

Trumpf didn’t just adopt omlox—they helped create it. As a founding member of the open standard, Trumpf and omlox ensured interoperability and scalability across industries, from aerospace to automotive. “omlox Core Zone is the foundation. If you start there, you can scale step-by-step to a full Industry 4.0 factory,” Wahl emphasized. This strategic foresight also opens doors for vendors and OEMs: omlox ensures that devices, tags and systems from different suppliers can work together seamlessly—creating an ecosystem of innovation rather than isolated solutions.

Partnering with Qorvo: A Pioneering Journey

The collaboration among Trumpf, omlox and Qorvo wasn’t just about product adoption—it was co-innovation. “We were pioneers. There wasn’t a roadmap, so sometimes it was trial and error,” Wahl recalled. “But Qorvo’s support and reliable chipsets made the journey a success.” Using Qorvo’s UWB in Band 9, Trumpf built what it now calls omlox Air 8—a highly reliable, scalable system that forms the backbone of its smart factories.

Looking Ahead: UWB as a Competitive Necessity

Wahl sees UWB-powered RTLS not as a luxury but as a future requirement for any competitive manufacturing operation. “At some point, there will be no significant level of production without omlox and UWB,” he stated. “It will simply be a must.” Trumpf’s transformation is a powerful proof point: UWB location technology isn’t just hype—it’s a strategic investment with measurable ROI. Companies looking to lead in Industry 4.0 should take note of Trumpf’s blueprint: Start with UWB, plan for scalability and partner with proven innovators like Qorvo and omlox.

Have another topic that you would like Qorvo experts to cover? Email your suggestions to the Qorvo Blog team and it could be featured in an upcoming post. Please include your contact information in the body of the email.