The Portable Revolution: Qorvo Powers the Shift to Smarter, Battery-Driven Systems

August 14, 2025

From garden tools to humanoid robotics, the demand for advanced battery management and motor control technologies is accelerating at a pace few could have imagined a decade ago. At the heart of this transformation is Qorvo, which has firmly established itself as a leader in delivering high-performance, highly integrated solutions for battery-powered systems across a broad voltage spectrum.

Qorvo Product Line Management Director Brian McCarthy sees parallel trends driving the current and future growth of the company’s business: the widespread shift to battery-powered systems, and the universal move to brushless DC (BLDC) motors.

“Everything is moving to portable, rechargeable batteries,” Brian said. “From e-bikes and ride-on lawn tractors to drones and robotics, there’s a clear trend toward electrification, and these applications require smarter power management and more precise motor control.”

Filling the Mid-Voltage Gap

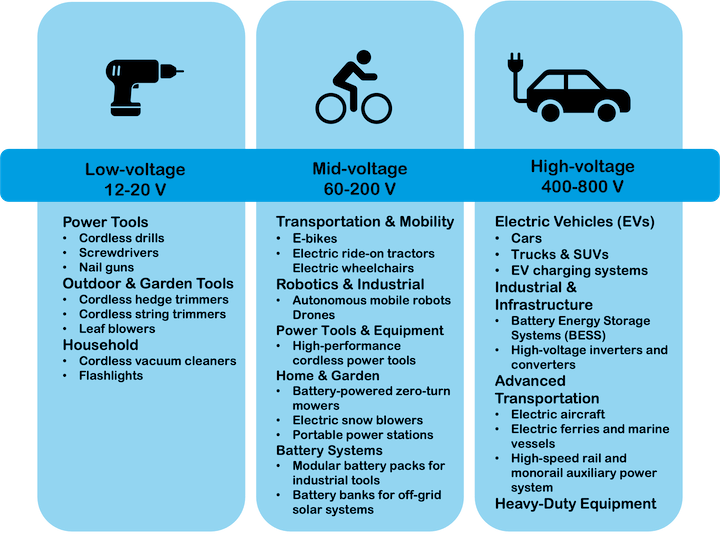

Historically, the power electronics market has been split between low-voltage tools like cordless drills (12–20V) and high-voltage electric vehicles (400–800V). But today, an emerging class of industrial and commercial products, like e-scooters, agricultural drones and robotic systems, is rapidly filling the mid-voltage gap (48–100V). This is where Qorvo sees one of its greatest opportunities.

“We’re very well positioned in that medium voltage space,” Brian notes. “Our battery management systems (BMS) support up to 20 lithium-ion cells on a single chip. That means up to 80 volts with just one chip, while many competitors still require stacking multiple chips to support these voltage levels.”

This single-chip solution not only reduces cost and board complexity but also improves safety and reliability - key selling points for OEMs building scalable battery-powered platforms.

Learn about DC voltage regulators, key differences between linear and switching types, power management applications, and strategies to reduce EMI and noise ripple in switching regulators.

“We’re very well positioned in that medium voltage space,” Brian notes. “Our battery management systems (BMS) support up to 20 lithium-ion cells on a single chip. That means up to 80 volts with just one chip, while many competitors still require stacking multiple chips to support these voltage levels.”

This single-chip solution not only reduces cost and board complexity but also improves safety and reliability - key selling points for OEMs building scalable battery-powered platforms.

Motor Control at the Core

While Qorvo is gaining recognition in the BMS space, the company’s roots are in motor control. For more than a decade, Qorvo has been investing in BLDC motor control technology, developing compact, integrated solutions that offer greater efficiency and longer service life than brushed alternatives.

“Brushed motors are inefficient and wear out over time,” Brian said. “This helps drive the migration to the more reliable BLDC motor solutions. The control scheme for these applications is more complex, but this is where Qorvo steps in with highly integrated, complete hardware and firmware solutions to support our customers. Combining this with our increased investment in companion battery management products makes us the complete system solution provider that many people are looking for.”

This dual investment strategy allows Qorvo to serve as a one-stop shop for customers seeking both power management and motion control capabilities. The integration of both technologies enables smaller form factors, faster development times, and superior system performance. These can be critical advantages in fast-growing markets like robotics and e-mobility.

Looking Ahead: Robotics, AI and Beyond

As artificial intelligence and automation take center stage, the next frontier in power and motion is humanoid robotics - machines with dozens of small motors packed into tight spaces. Brian believes this market will demand ultra-compact, high-efficiency systems, a challenge Qorvo is already preparing to meet.

Additionally, Qorvo is investing in battery chemistry expertise to keep pace with evolving materials, such as sodium-ion, which may offer safer and more sustainable alternatives to lithium-ion in the future.

Unique Adaptability

Qorvo’s Motor and BMS offerings are based on fully programmable industry-standard ARM Cortex MCUs. This enables customers to add their own IP to help differentiate their solutions. Qorvo is helping enable them with new ways to differentiate themselves, such as adding Tiny Machine Learning (TinyML) algorithms for things like state of charge estimation and motor failure detection.

From high-performance drones to autonomous robots, and from smart garden tools to AI-powered delivery systems, Qorvo is enabling the electrified future, not just by anticipating market needs, but by actively engineering what comes next. Leadership in battery management and motor control represents a powerful opportunity to help customers accelerate innovation, simplify design, and lead in their respective markets.

Find out more about Qorvo's power solutions here.

Have another topic that you would like Qorvo experts to cover? Email your suggestions to the Qorvo Blog team and it could be featured in an upcoming post. Please include your contact information in the body of the email.