Wi-Fi Innovation Simplified

Greater Coverage & Speed for a More Connected World

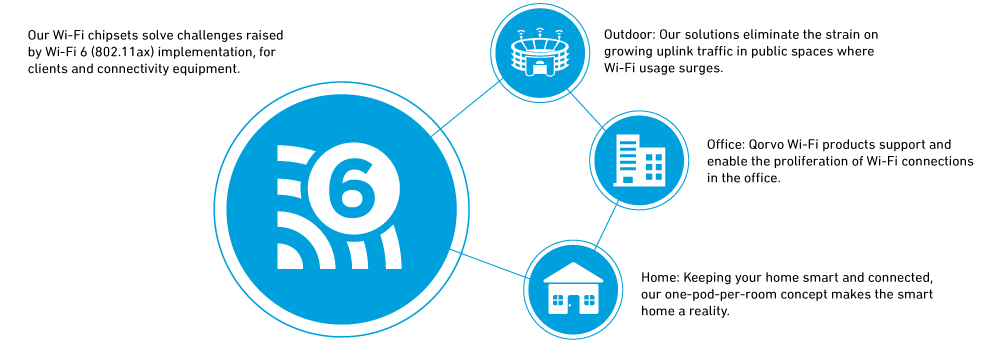

Wi-Fi 802.11ax, also known as Wi-Fi 6, advances wireless communications yet again – bringing broader coverage for the entire smart home, office building, or outdoor space. Qorvo simplifies Wi-Fi 6 design with device and system solutions for IoT, customer premises equipment, gateways and infrastructure with 802.11ax filtering technologies, integrated front-end modules (iFEMs) and "pod in every room" architecture for distributed Wi-Fi (Wi-Fi Mesh).

For more information on Wi-Fi 6, Wi-Fi 6E (6 GHz) and the IoT, check out our engineering resources.

New Wi-Fi Products

Wi-Fi 6 Is Here

Spotlight on Wi-Fi 6

Wi-Fi 6 (802.11ax) is the next evolution in the IEEE 802.11 Wi-Fi standard. Promising faster data rates, better coverage in dense urban environments and the home, and support for uplink MIMO, it brings many challenges for Wi-Fi product designers.

Learn what’s most important when designing for this new standard:

- NEW: E-Book: Next-Gen Wi-Fi Applications and Solutions Design Guide

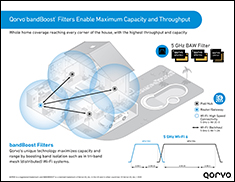

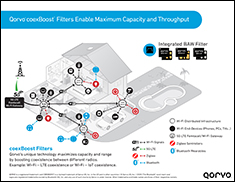

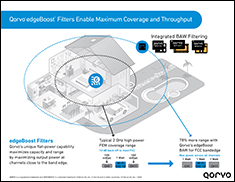

- edgeBoost™, bandBoost™ and coexBoost™ – Three Types of Wi-Fi Filters

- 6 Key Elements of Wi-Fi 6 (802.11ax) Infographic

- The Wi-Fi Evolution

- Wi-Fi 6 (802.11ax): 5 Things to Know

- Designing for Wi-Fi 6 (802.11ax): Common Challenges and Tips to Overcome Them

- Wi-Fi 6: Wi-Fi Regulatory Roadmap and Beyond

- The New Wi-Fi 6 Standard: Combining Software and Hardware for Best-in-Class Solutions

Infographics - Our Latest Wi-Fi Technology

With multiple RF standards coexisting with Wi-Fi networks, Qorvo’s BAW (bulk acoustic wave) filter technology helps designers meet system-level specifications in Wi-Fi 6 and 6E while mitigating cross-over interferences. Learn how Qorvo’s Wi-Fi filters solve three challenges in Wi-Fi systems to improve capacity, range and throughput performance while eliminating unexpected degradation.

View Our Related White Paper: edgeBoost, bandBoost and coexBoost – Three Types of Wi-Fi Filters

Cees Links: Wi-Fi Pioneer

Cees Links (pronounced "Case"), retired general manager of Qorvo's Wireless Connectivity Business, is an industry visionary. From helping to establish the Wi-Fi Alliance and IEEE 802.11 standardization committee, to bringing the first consumer Wi-Fi products to market with popular computer makers, his work established broad acceptance of the technology used by billions today.

He founded and served as CEO of GreenPeak Technologies, which Qorvo acquired in 2016 for its leadership in IoT. He inspired the Wi-Fi industry earning accolades such as the Golden Mousetrap Lifetime Achievement Award from Design News and induction into the Wi-Fi NOW Hall of Fame. A prolific writer and author; his e-book The Spirit of Wi-Fi is available for download.

Gain more insights from Cees on wireless connectivity:

Explore Our Wi-Fi & IoT Solutions

Engineering Resources

Engineers face tough challenges when designing Wi-Fi products. See how you can improve your Wi-Fi design with smart choices for components, cost and partners.

- More Power! Engineering Insights for Optimizing Wi-Fi Power Consumption

- Enabling Coexistence: Strategies for Addressing Wi-Fi Interference

- All Data Sheets Are Not Created Equal: How to Compare and Contrast Key Parameters for Your Next Wi-Fi Design

- Overcoming MIMO Wi-Fi Front End Thermal Design Challenges

- Vendor Selection 101: Key Considerations When Choosing a Wi-Fi Partner

- A Step-by-Step Guide to Selecting the Best Wi-Fi Components for Your Application

- Video: How to Identify a Wi-Fi RF Front-End Failure

Browse Our Design Hub

Procurement

If you're responsible for procuring Wi-Fi products, here are resources just for you.

- Strategic Sourcing for Wi-Fi Designs: Impact on Profitability

- Strategic Wi-Fi Component Sourcing: Keeping Focus on Solution Cost Considerations

- Six Ways to Reduce Overall Wi-Fi Product Costs: Focus on Total Value

- Guide to Working Wi-Fi Costs into Your Design Budget

- 5 Things You Should Pay Attention to When Selecting a Wi-Fi Front End Solution

- The Qorvo Difference: Your Smart Partner for Innovative Wi-Fi Applications

- Partnering for Success: A Guide to Choosing a Quality Wireless Vendor

We're Here to Help

Browse Innovation

-

The Matter-Enabled IoT

Matter interoperability is a key driver for enablement and acceptance of the IoT and its devices in our wireless world. The new Matter standard will improve the interoperability between these IoT devices and standards. From a system developers standpoint interoperability can make the difference with product acceptance. It can also help in the actual design and functionality of the IoT device being created. -

Power Solutions

We're building a new type of power. Over multiple decades, Qorvo has built and delivered the industry's best RF products, all based on deep manufacturing and compound semiconductor expertise. Now, Qorvo is strengthening its portfolio with best-in-class smart power management products.